How much do you know about biofermentation?

Release time:

19 Aug,2024

Summary

In the vast field of life sciences and biotechnology, biofermentation, as an ancient and powerful technology, has always held a pivotal position. From food brewing to the pharmaceutical industry, from agricultural feed to environmental protection, the applications of biofermentation are ubiquitous, bringing many conveniences and innovations to our lives. In this process, gas flow meters, as one of our company's core products, have also demonstrated their unique value and applications in the field of biofermentation.

Biofermentation Principle

environmental protection

Biofermentation, in short, is the process of using microorganisms (such as bacteria, fungi, and yeast) under specific conditions to convert organic substances into useful products through metabolic activities. In this process, microorganisms use enzymatic catalysis to convert substrates (such as sugars and proteins) into target products, such as alcohol, lactic acid, organic acids, and enzyme preparations. According to the different metabolic pathways of microorganisms, biofermentation can be divided into two major categories: aerobic fermentation and anaerobic fermentation.

Aerobic fermentation: Under sufficient oxygen conditions, microorganisms completely oxidize the substrate through aerobic respiration, producing carbon dioxide and water, and releasing a large amount of energy.

Anaerobic fermentation: Under anaerobic or hypoxic conditions, microorganisms partially oxidize the substrate through anaerobic respiration, producing lactic acid, alcohols, gases, and other products, accompanied by the release of a small amount of energy.

Application of Gas Flow Meters in Biofermentation

environmental protection

In the biofermentation process, precise control of gas flow is crucial to ensuring fermentation efficiency and product quality. Our gas flow meters, with their advantages in measurement accuracy, stability, and automated control, have become indispensable tools in the biofermentation industry.

Oxygen flow control: In aerobic fermentation, the supply of oxygen directly affects the growth rate and metabolic activity of microorganisms. By installing our gas flow meter, the oxygen flow in the fermenter can be monitored and controlled in real time, ensuring that the microorganisms grow under the optimal oxygen concentration, thereby improving fermentation efficiency and product quality.

Carbon dioxide emission monitoring: In anaerobic fermentation, the carbon dioxide produced by microbial metabolism is one of the important indicators for judging the fermentation status. By monitoring the carbon dioxide emission with a gas flow meter, the fermentation conditions can be adjusted in time to avoid excessive accumulation of carbon dioxide leading to abnormal fermentation.

Nitrogen protection: In some specific biofermentation processes, in order to prevent contamination by foreign bacteria and maintain the stability of the fermentation environment, nitrogen gas needs to be introduced into the fermenter. Our gas flow meter can precisely control the flow rate of nitrogen gas to ensure the purity and stability of the fermentation environment.

Practical Application Cases

environmental protection

In the pharmaceutical industry, biofermentation technology is widely used in the production of antibiotics, vaccines, and other biological products. By installing our gas flow meter, pharmaceutical companies can achieve precise control of oxygen, carbon dioxide, and other gases during the fermentation process, ensuring that microorganisms grow and metabolize under optimal conditions, improving product purity and yield. At the same time, the automated control system can also reduce manual intervention, reduce operational risks, and improve production efficiency.

Qingdao Xinnovis gas flow controllers can be mainly applied to the following equipment during the biofermentation stage:

Bioreactor:

The bioreactor is the core equipment in the biofermentation process, used to control the growth environment and metabolic conditions of the microorganisms. Xinnovis's gas flow controller can precisely control the flow rate of oxygen, carbon dioxide, nitrogen, and other gases in the reactor, ensuring that the microorganisms grow under optimal conditions, thereby improving product quality and yield.

Gas distribution system:

In the biofermentation process, it is necessary to accurately adjust the proportions of various gases according to different fermentation stages and microbial needs. Xinnovis gas flow controllers can be used in gas distribution systems to achieve precise proportioning and flow control of multiple gases, ensuring the stability and reliability of the fermentation process.

Fermenter:

The fermenter is a container used to cultivate microorganisms in the biofermentation process. Xinnovis's gas flow controller can be used to control the inflow and outflow of gases in the fermenter, including oxygen and carbon dioxide, to maintain a suitable gas environment in the tank and promote the growth and metabolism of microorganisms.

The application of Qingdao Xinnovis gas flow controllers in the biofermentation stage has the following advantages:

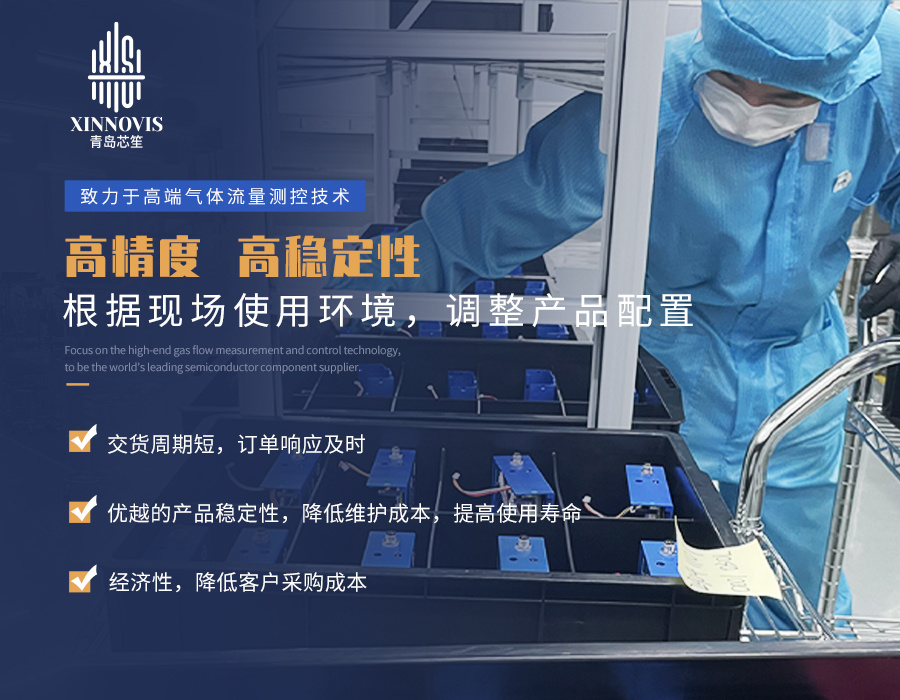

High precision :

Qingdao Xinnovis uses advanced flow sensing technology and high-precision control circuits to achieve precise measurement and control of gas flow, meeting the strict requirements of biofermentation processes for gas flow accuracy.

High stability :

It features good long-term stability, maintaining stable performance under various environmental conditions, ensuring the continuity and reliability of the biofermentation process.

Easy to maintain :

The design of the gas flow controller considers ease of maintenance, with a compact structure and simple operation, making it easy for users to perform daily maintenance and upkeep, reducing operating costs.

Multifunctionality :

It not only has basic flow control functions but also powerful data processing and communication functions, enabling remote monitoring and control, improving production efficiency and automation levels.

Wide applicability :

The gas flow controller covers a wide range of flow rates, meeting the gas flow requirements of different biofermentation processes, and is suitable for various gas media, with high versatility and flexibility.

In summary, the application of Qingdao Xinnovis gas flow controllers in the biofermentation stage has significant advantages, improving the stability and reliability of the biofermentation process and increasing product quality and yield.

Conclusion

environmental protection

Biofermentation, as an ancient and powerful technology, continues to thrive in the field of modern biotechnology. Gas flow meters, as important monitoring tools in the biofermentation process, are undeniably important. As a professional gas flow meter manufacturer, we will continue to focus on technological innovation and product optimization to provide the biofermentation industry with more advanced and reliable solutions. We look forward to working with more partners to jointly promote the prosperity of biotechnology!

More News

Tel: 400 006 6550

Office Address: 12. Stock, Gebäude I, Internationaler Innovationspark, Nr. 177 Songling Road, Laoshan District, Qingdao