Precautions for measuring hydrogen flow meters, come and collect!

Release time:

28 May,2023

Summary

A hydrogen flow meter is a flow instrument widely used in industrial automation control systems. Hydrogen is a very special gas with high combustion performance and fragility, so special attention should be paid to safety issues during its use. This article will introduce the precautions for measuring hydrogen flow meters and the benefits of using hydrogen flow meters.

Precautions for measuring hydrogen flow meters: Hydrogen is a very dangerous gas with explosiveness and flammability, so safety precautions should be taken when using a hydrogen flow meter. Before using the hydrogen flow meter, it needs to be strictly inspected to ensure its safety and reliability. Avoid fire sources and static electricity around the hydrogen flow meter.

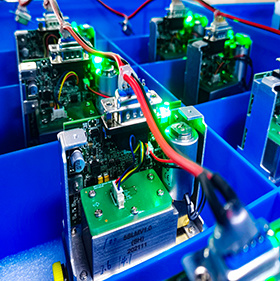

When using a hydrogen flow meter, attention should be paid to the inspection of the equipment. Equipment inspection should include checking the wiring, checking whether the cable plugs are loose, and checking whether the accuracy of the hydrogen flow meter meets the required range.

The placement of the hydrogen flow meter should be avoided as much as possible to prevent contamination. When placing the hydrogen flow meter, a dry and clean place should be selected, and a certain distance should be maintained between the selected location and other equipment. In addition, care should be taken not to obstruct its sensor when placing the hydrogen flow meter.

Calibration of the hydrogen flow meter is an issue that needs attention when using a hydrogen flow meter. Before using the hydrogen flow meter, it needs to be calibrated to ensure its accuracy. During the calibration process, attention should be paid to the selection of the calibration equipment to ensure the accuracy of the calibration.

Hydrogen flow meters are widely used in industrial production, and their use can bring the following benefits:

Using a hydrogen flow meter can achieve automated control, thereby improving production efficiency. The hydrogen flow meter can quickly and accurately measure the flow rate of hydrogen, accurately reflect the use of hydrogen at the production site, and provide more accurate data support for enterprise production.

Using a hydrogen flow meter can reduce energy consumption. Quantifying and controlling the use of hydrogen in the production process avoids waste and unnecessary consumption during production, thereby saving energy.

The hydrogen flow meter can ensure that the flow control in the production process is accurate and stable, thereby ensuring product quality. Using a hydrogen flow meter can accurately monitor the production process, promptly identify problems and adjust them in time, thereby ensuring the stability of production quality.

The hydrogen flow meter can replace traditional manual measurement, thereby reducing labor input and saving labor costs. Using a hydrogen flow meter can achieve automated control, greatly reducing the workload of staff, so that enterprises can use human resources more efficiently.

A hydrogen flow meter is a very important industrial flow instrument, and its use can bring many benefits. However, when using a hydrogen flow meter, we should also pay attention to its safety issues to ensure the safety and stability of the company's production and working environment.

More News

Tel: 400 006 6550

Office Address: 12. Stock, Gebäude I, Internationaler Innovationspark, Nr. 177 Songling Road, Laoshan District, Qingdao