National Science and Technology Innovation Deployment during the 14th Five-Year Plan Period: Market Status Analysis of Core Technologies for Gas Flow Measurement and Control

Release time:

26 Aug,2022

Summary

Addressing the major strategic needs of the nation's basic research and technological innovation, breaking through key technologies that have been a bottleneck for foreign countries, achieving domestic production of key core components 。 project The project prioritizes support for the engineering development and application of high-end scientific instruments, developing reliable, durable, user-friendly, and high-end scientific instruments that users are willing to use. or its core components , effectively enhancing China's independent innovation capabilities and equipment level in scientific instruments, promoting industrial upgrading and development, and supporting the implementation of the innovation-driven development strategy.

Gas flow is one of the most conventional physical quantities detected, and gas flow measurement and control in industrial process control 、 semiconductors, photovoltaics, fuel cells, analyzers, aviation aerospace , medical and scientific research, etc. various industries all play an extremely important role, and their status and research value in national economy and people's livelihood are also increasing. 。 Gas mass flow meter ( Mass Flow Meter, MFM ) used for gas flow measurement, Gas mass flow controller ( Mass Flow Controller, MFC ) consists of a gas mass flow meter and a proportional valve, used for precise control of gas flow. precise control , Its market size exceeds 300 hundreds of millions of yuan / per year, driving a market size exceeding 10 trillions of yuan / per year.

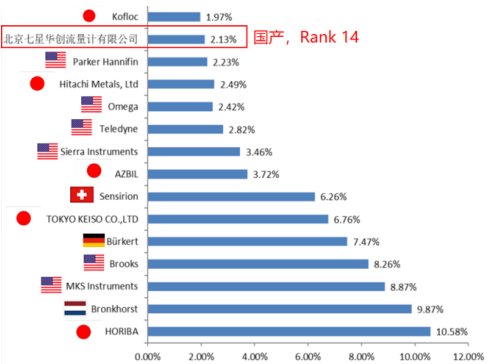

Currently, the gas mass flow controller market is mainly dominated by European and American brands. As shown in the figure, 1 shown, 2019 year gas mass flow controller market share top 15 brands, only Beijing Seven Star Huachuang is on the list among domestic brands, and the total market share of domestic brands is less than 3% . Especially in semiconductor etching machine , satellite attitude control instrument 、 ICP mass spectrometer manufacturing in high-end products required MFC products , Currently completely dependent on imports, this market is American MKS 、 Japanese Horiba 、 Dutch Bronkhorst and other European and American companies so monopolized, seriously affecting the development of the country's high-end instrument and equipment.

Figure 1 2019 Year Gas Mass Flow Controller Market Ranking

With the development of semiconductor technology and high-end equipment, traditional differential pressure mass flow controllers and capillary-based thermal mass flow controllers can no longer meet the requirements. MEMS mass flow controllers have been rapidly developed due to their high sensitivity, fast response speed, large range ratio, and strong anti-pollution ability. European and American brands have successively deployed MEMS thermal mass flow controllers, while domestic brands are still mainly capillary thermal mass flow controllers from Beijing Seven Star Huachuang, which has led to an increasing gap between domestic and foreign products. On the other hand, with the continuous sanctions from the United States, the import of proportional valves used in mass flow controllers is also restricted. The insufficient capacity of domestic proportional valves has undoubtedly exacerbated the technological " bottleneck ” " situation.

Therefore, semiconductor-grade mass flow controllers and their core components research and development will help solve national " bottleneck ” problems and enhance the chain security of important industries such as semiconductors. This project intends to MEMS conduct research on industrial-grade flow sensor chip preparation, piezoelectric proportional valve development, and circuit and control algorithm model optimization to solve " two core ” , improve " one model ” as the route, to develop gas mass flow controller products with stable performance and reliable quality, and to form mass production capacity, replacing domestic products in semiconductor, photovoltaic, analyzer, aviation, medical and other industry equipment, and breaking the foreign monopoly.

Industry Chain Analysis

Gas mass flow controllers, as core components of semiconductor equipment, satellite attitude control equipment, ICP mass spectrometers, etc., currently mainly rely on imports and are seriously subject to Western countries such as Europe and the United States. Therefore, the domestic production of gas mass flow controllers will directly affect the development and domestic production process of high-end scientific analytical instruments and advanced semiconductor equipment.

Therefore, as the technical basis for gas mass flow controllers, MEMS the development of flow sensor chips and proportional valves is crucial. Only by successfully developing high-performance, high-reliability MEMS chips and proportional valves, combined with advanced circuits and control algorithms, can gas mass flow controllers be manufactured that are comparable to European and American products, breaking the foreign monopoly and overcoming " bottleneck ” restrictions, achieving the domestic production of high-end instruments and equipment, and enhancing the chain security of important industries such as semiconductors and national defense.

Analysis of Core Technological Difficulties

I. Industrial-grade MEMS preparation of flow sensor chips. Existing MEMS flow sensor chips usually prepare heating elements and sensitive elements on a suspended membrane, with poor structural stability. Deformation or even rupture of the suspended membrane will directly affect the performance of the device; on the other hand, when the chip is contaminated, damp, or worn, it may lead to inaccurate or even invalid measurement results. Therefore, how to improve MEMS the stability and reliability of flow sensor chips is a core technological difficulty.

II. Development of piezoelectric proportional valves. On the one hand, the production of domestic mass flow controllers currently mainly relies on imported electromagnetic proportional valves. With the intensification of sanctions, the domestic production of proportional valves is particularly important; on the other hand, traditional proportional valves generally use electromagnetic technology, using the electromagnetic force generated when the coil is energized to control the movement of the valve core. The structure is complex, the response speed is slow, the power consumption is high, the anti-interference ability is poor, and it is easy to damage. Therefore, the development of piezoelectric proportional valves with high precision, low power consumption, fast response, and anti-electromagnetic interference is another core technological difficulty.

Economic and Social Benefit Calculation

" Since the 13th Five-Year Plan ” period, with the advancement of Made in China 2025 initiative, driven by rapidly growing domestic demand, China's equipment manufacturing industry has made significant progress, and its major technological equipment independent innovation capabilities have been significantly improved. However, due to foreign restrictions on China's high-performance MEMS chips and key core components, severely restricting China's development of high-end instruments and equipment, leading to the national economy and national defense security being subject to others. MEMS Flow sensor chips 、 Piezoelectric proportional valves and semiconductor-grade gas mass flow controllers can break foreign monopolies and improve the industry's technological level, playing a very good promoting role, and are expected to achieve significant socio-economic benefits.

Through the research on gas mass flow controllers and their core components in mass production research 、 can form independent intellectual property rights in the entire chain of core technologies such as chips, modules, and intelligent algorithms, enabling China's mass flow controllers and downstream high-end instrument and equipment industries to develop independently and controllably, breaking the foreign monopoly on gas mass flow controllers and their processing platform technology and market monopoly, changing China's gas mass flow controllers long-term reliance on imports 、 and the predicament of being subject to others, enhancing China's high-end instrument and equipment independent innovation capabilities, promoting domestic substitution is conducive to the reasonable layout of the national industrial ecosystem and enhances the chain security of important industries such as semiconductors and national defense.

No reproduction without permission!

More News

Tel: 400 006 6550

Office Address: 12. Stock, Gebäude I, Internationaler Innovationspark, Nr. 177 Songling Road, Laoshan District, Qingdao